Hello everyone! I haven't posted anything in a while but I wanted to share this latest project with you.

I'm a do-it-yourself kind of guy. So, recently, when my transmission went out on my car, I decided that this time I would rebuild it myself. I also realized that I'm lacking in a few necessary tools to do this kind of work, namely a transmission jack. So, I got to thinking.....and drawing with ViaCAD. And, here's what I came up with.

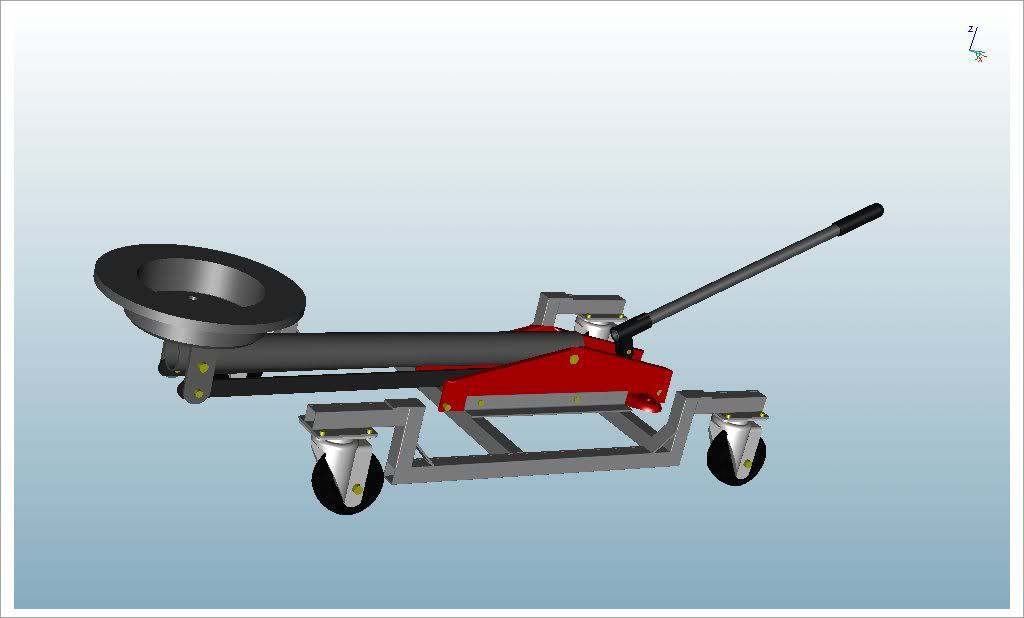

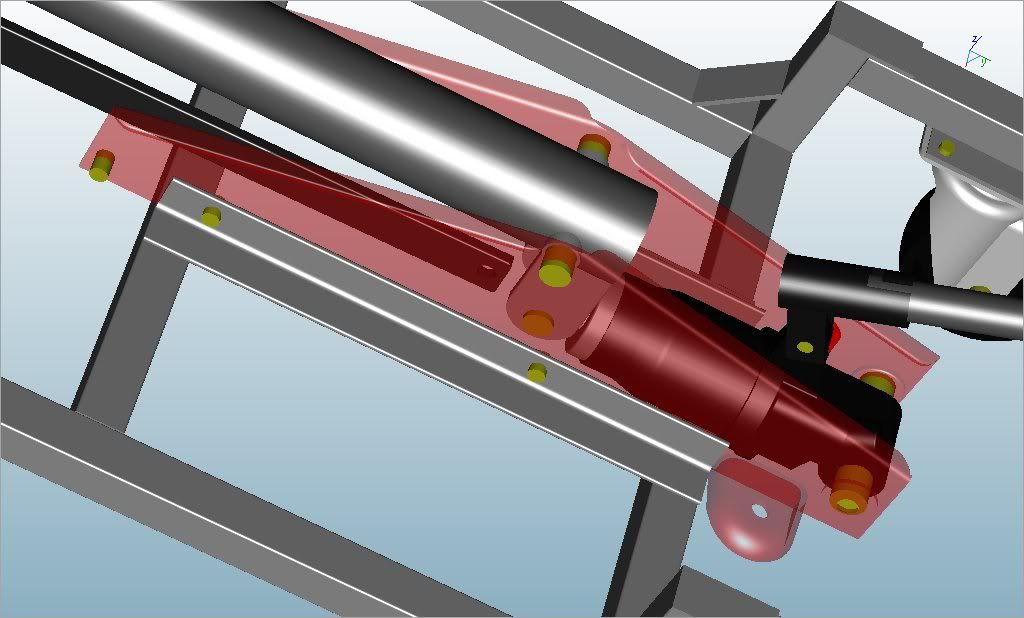

This is a design for converting a normal two ton floor jack into a handy transmission or accessory jack. I started by reverse engineering a cheap MVP floor jack that I had in my garage and then digitally converting it into a handy jack capable of lifting a slightly lighter load (500lbs, give or take) but with a much wider range of lift. Originally, the floor jack had only about 8" of lifting range. So, I redesigned it to have about 24" of lifting range, more than enough to remove a transmission from a car.

Here's what the original jack looks like:

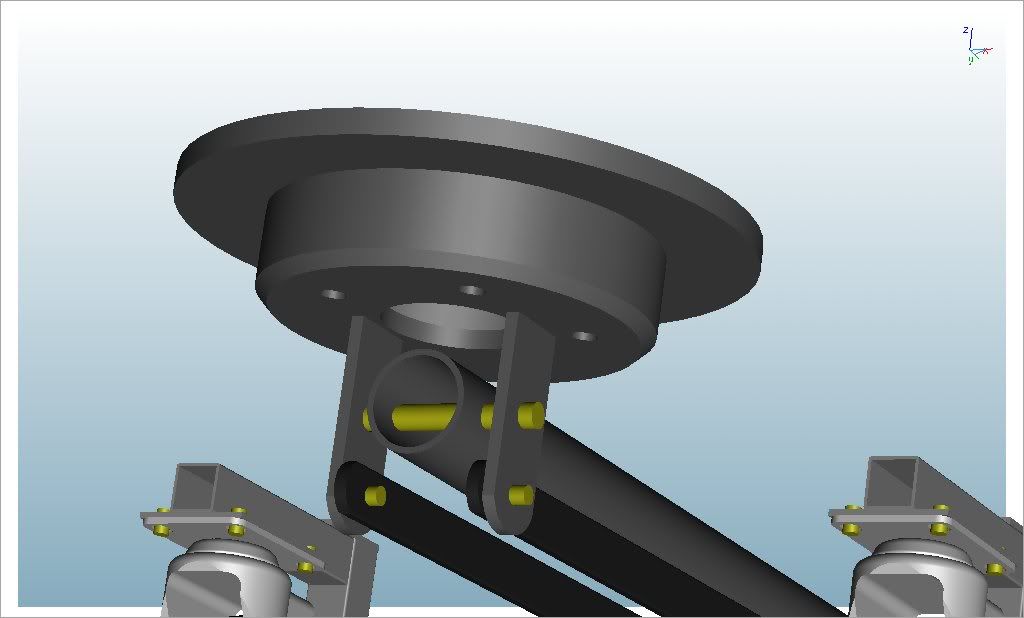

Another thing I decided to do to simplify things is to recycle an old brake rotor to use for the head of the jack. The 11" rotor provides more than enough square inches required for a stable lift.

ViaCAD Pro wasn't just useful for constructing a 3D model of my idea, but even before I began modeling the actual jack, I started by using some very simple line drawings to work out the geometry challenges. ViaCAD Pro was the perfect tool for this.

Now, this is a very simple model. I did a very quick simple model of the components that I planned to re-use from the original jack, including the pump, the handle, the ram and the frame. I also modeled some swivel castors that I purchased from Harbor Freight. In place of bolts, I just did some quick extrusions of appropriately sized circles.

Here's the result:

I have actually built this jack over the weekend and it turned out great. As soon as I can, I will upload pictures of the actual product. ViaCAD has become one of the most important tools I have!